As a promising candidate in the new generation of energy storage technologies, lithium-ion batteries (LIBs) have rapidly developed and are widely used in traditional consumer electronics products to large-scale energy storage systems. Due to the increased demand in extreme environmental conditions, such as in cold polar regions and hot arid regions, batteries can operate at -30° C to 100° Operate within a wide temperature range of C. However, many studies have shown that the effect of temperature on the electrochemical performance of LIBs at high and low temperatures can be affected. In fact, in electric vehicles (EVs), the operating temperature range of LIBs is 15 degrees Celsius; C to 35° C. The electrochemical performance of batteries is affected by extreme environmental conditions. For example, at low temperatures, an increase in the viscosity of the electrolyte can lead to a rapid decrease in ion conductivity; At high temperatures, the charge transfer resistance of the cathode increases. Meanwhile, polymer materials in batteries, such as binders, become fragile and lose their original performance at low temperatures, thereby reducing their electrochemical performance. The chemical effects related to extreme conditions are mainly due to structural changes in electrode materials. Recently, there have been reports that high operating temperatures can accelerate the dissolution of metal layers and the release of oxygen in layered cathode materials. In addition, irreversible structural damage to the cathode can be observed at low temperatures through a full field transmission X-ray device. Therefore, although it is challenging, it is very important to have a deep understanding of the influence of temperature parameters on the internal electrode structure of LIBs.

Product details:

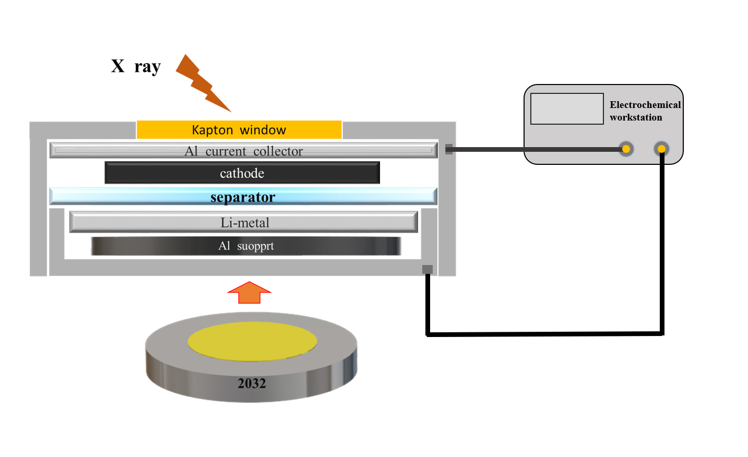

The XRD in-situ lithium battery device (ISXRD-LIB102) can achieve in-situ XRD testing during the charging and discharging process of lithium batteries, to observe the structure and phase transition of electrode materials during the charging and discharging process, and accurately reveal the battery reaction mechanism. The window panel is a high-purity Be window.

The XRD in-situ lithium battery device can be equipped with a support frame and Z-axis displacement table, which can be adapted to universal X-ray diffractometers such as Thermo Fisher, Brooke, Science, Shimadzu, etc.

Main features:

In situ testing of X-ray diffraction spectrum data under reflection mode during normal charging and discharging of lithium batteries;

Large detection angle of X-rays: 7 °<2 θ< 164 °;

The main material is 316L stainless steel, which has strong corrosion resistance;

Compact size, card slot structure matched with Z-axis displacement table, easy installation, and adjustable height;

Reusable, inverted installation of electrode materials and electrolytes, easy assembly, ensuring sealing performance after repeated disassembly and assembly;

The sealing structure is specially designed to ensure the sealing performance after multiple disassembly and assembly;

The overall disassembly and assembly of the device is extremely convenient and fast, and each battery component is easy to clean. The installation/disassembly process is simple

Schematic diagram of in-situ battery XRD testing: