The ARL SMS-3500 automation technology suitable for Twin OES or XRF provides a single injection location with film storage function for all samples,

No sample injection is required, simplifying the sample processing process. This can reduce reaction time, accelerate the pace of sample processing, and improve the availability of automatic sample preparation function in extreme production control environments.

main features

Eliminating time-consuming electromechanical transmission systems: The SMS-3500 automation equipment can move samples between system components within seconds.

The ARL SMS-3500 simplifies operations, reduces system complexity, and is therefore easy to maintain and use.

A single interface can provide a complete set of sample tracking and automated user functions.

The single registration device and injection location can be used for all production samples, and the latter can be automatically guided to the corresponding system components

Dual sample preparation equipment support can reduce reaction time, accelerate the pace of sample processing, and improve the availability of automatic sample preparation function in extreme production control environments

Simplify operator work: The automation system can optimize reaction time and manage samples based on sample priority, available sample preparation, and analytical resources. The internal sample storage capacity can immediately eliminate the need for subsequent sample injection operations

All instruments can be manually operated offline without interrupting automated system operations.

XRF and OES applications use the same analysis software, and automation control is based on validated ARL SMS software.

Suggested for:

Steel applications

High alloy, stainless steel, copper, brass, and bronze applications

Application of aluminum or fire assay method

ARL iSpark Plus series OES direct reading spectrometer

ARL iSpark Plus series OES direct reading spectrometer ARL iSpark 8860 Inclusion Analyzer

ARL iSpark 8860 Inclusion Analyzer ARL ™ ISpark 8860 Fire Assay Analyzer

ARL ™ ISpark 8860 Fire Assay Analyzer ARL for OES or XRF ™ SMS-2300 Automation System Based on Automation Equipment

ARL for OES or XRF ™ SMS-2300 Automation System Based on Automation Equipment ARL SMS-3300 automation system with single or dual OES or XRF

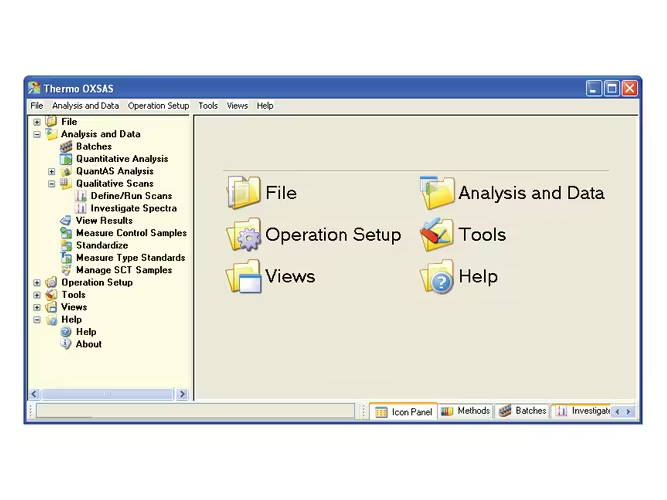

ARL SMS-3300 automation system with single or dual OES or XRF OXSAS ™ Direct reading spectroscopic analysis software

OXSAS ™ Direct reading spectroscopic analysis software