The ARL iSpark Plus series uses high-performance PMT (photomultiplier tube) optical components and is a high-performance OES direct reading spectrometer platform. It is more powerful and equipped with other innovative technologies:

ARL iSpark Plus version

Compared to previous models, the analysis time is reduced by 15%

Extend maintenance interval by 30%

Has almost no memory effect on the main matrix

Improved stability

Other features and advantages:

Unique PMT optical components

Revolutionary digital spark generator

Innovative Spark Table Design

Provide excellent analytical performance in terms of accuracy, precision, and detection limit

Multipurpose analysis applicable to all metal markets, including major metal producers, metal processors, foundries, contract laboratories, and recyclers

Real factory calibration using good available reference materials

Faster online analysis of non-metallic inclusions, including quantitative size analysis of killed steel

Revolutionary intelliSource dual CCS (current control source) for excellent analysis of each substrate

Advanced signal acquisition technology and processing algorithms

Single spark collection using diffusion spark intensity removal algorithm can improve the accuracy of PMT

Intelligent argon management, equipped with argon saving mode

Automation solution using ARL SMS products

Advanced technology/service support

All of these features help optimize productivity and achieve a short-term return on investment:

Reduce investment costs by:

Long instrument lifespan and sustainable upgrade capability (software and hardware)

The instrument functions can meet your future needs

Reduce production costs by:

Conduct more accurate and reproducible analysis in the shortest possible time

With high stability and low drift correction frequency, the availability of the instrument is improved

Reduce operational and maintenance costs by:

Drift correction samples have low consumption and simple maintenance

Significant savings in argon gas during analysis intervals

Reduce overall cost management by:

Make full use of materials

Compared to other methods, it has lower operating costs.

ARL iSpark 8860 Inclusion Analyzer

ARL iSpark 8860 Inclusion Analyzer ARL ™ ISpark 8860 Fire Assay Analyzer

ARL ™ ISpark 8860 Fire Assay Analyzer ARL for OES or XRF ™ SMS-2300 Automation System Based on Automation Equipment

ARL for OES or XRF ™ SMS-2300 Automation System Based on Automation Equipment ARL SMS-3300 automation system with single or dual OES or XRF

ARL SMS-3300 automation system with single or dual OES or XRF ARL for Twin OES or XRF ™ SMS-3500 automation technology

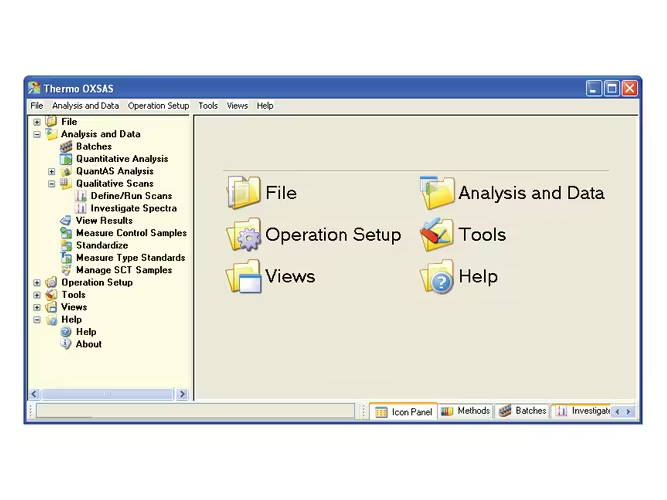

ARL for Twin OES or XRF ™ SMS-3500 automation technology OXSAS ™ Direct reading spectroscopic analysis software

OXSAS ™ Direct reading spectroscopic analysis software