The ARL SMS-2300 automation technology suitable for OES or XRF is Thermo Scientific ™ ARL ™ 4460 or

ARL ™ ISpark direct reading spectrometer or Thermo Scientific ™ ARL ™ The automation and unmanned operation of the 9900 X-ray fluorescence spectrometer provide strong support and flexibility in all weather conditions.

main features

Specially designed for easy integration into fully automated laboratories.

The entire system can be installed in Thermo Scientific ARL QuantoShelter and placed very close to the production program.

Parallel execution of tasks; Inject or analyze other samples simultaneously during sample preparation; The spectrometer performs instrument rack cleaning during hidden time, independent of the ARL SMS-2300 robot.

Adopting an automated sample preparation solution with added features (including Thermo Scientific) ™ ARL ™ PrepControl ™ System and Thermo Scientific ™ ARL ™ EasyPrep ™ The software's Haas Mini Mill handles more samples.

Direct access to the Haas Mini Mill grinder to reduce processing time for ferrous samples. It can also directly reach other preparation machines (defined during project layout).

Configure and customize according to factory requirements.

Compact chassis and extremely simple installation.

Integrated electronic technology.

Better analysis, higher reliability and quality.

Quick recycling.

Faster result availability.

Liberate qualified laboratory personnel from routine work.

Production and maintenance according to ISO 9001 procedures.

Advanced technology

The most advanced Fanuc industrial robot

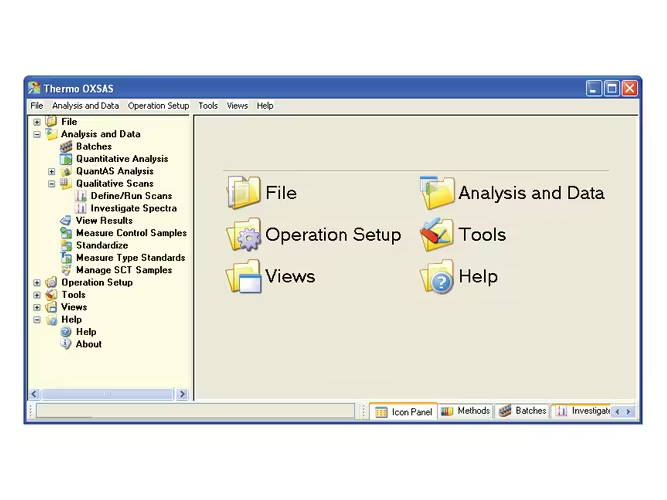

OXSAS analysis software

ARL iSpark Plus series OES direct reading spectrometer

ARL iSpark Plus series OES direct reading spectrometer ARL iSpark 8860 Inclusion Analyzer

ARL iSpark 8860 Inclusion Analyzer ARL ™ ISpark 8860 Fire Assay Analyzer

ARL ™ ISpark 8860 Fire Assay Analyzer ARL SMS-3300 automation system with single or dual OES or XRF

ARL SMS-3300 automation system with single or dual OES or XRF ARL for Twin OES or XRF ™ SMS-3500 automation technology

ARL for Twin OES or XRF ™ SMS-3500 automation technology OXSAS ™ Direct reading spectroscopic analysis software

OXSAS ™ Direct reading spectroscopic analysis software